An Order of Superlatives.

Terminal 2 in Kuwait will be the world‘s largest terminal to be LEED Gold certified.

Success stories in airport construction still exist. The latest example can be found at Kuwait International Airport‘s Terminal 2, which will soon open and become the new air hub for the Persian Gulf.

The world‘s largest airport structure with Gold certification.

The new terminal building is intended to achieve the Gold category under the LEED (Leadership in Energy and Environmental Design) certification system. This goal, by the way, was formulated by the highest authorities in Kuwait. This fact was confirmed by the Minister of Public Works and Minister of State for Communications and Information Technology, Dr. Rana Al-Fares, in a July 2021 press release. This will make Terminal 2 the world‘s largest terminal to receive this accolade. This internationally renowned certification evaluates a total of 9 different topics. These take into account the building‘s integration into the infrastructure and the responsible use of water and energy consumption.

The indoor air quality is also an essential aspect of this certification. The objective of this certification is to create a holistic valuation approach for the planning, construction, and operation of environmentally friendly buildings. Terminal 2 in Kuwait impressively demonstrates that this is also possible at locations subject to exceptional climatic conditions.

A Building Project of Superlatives.

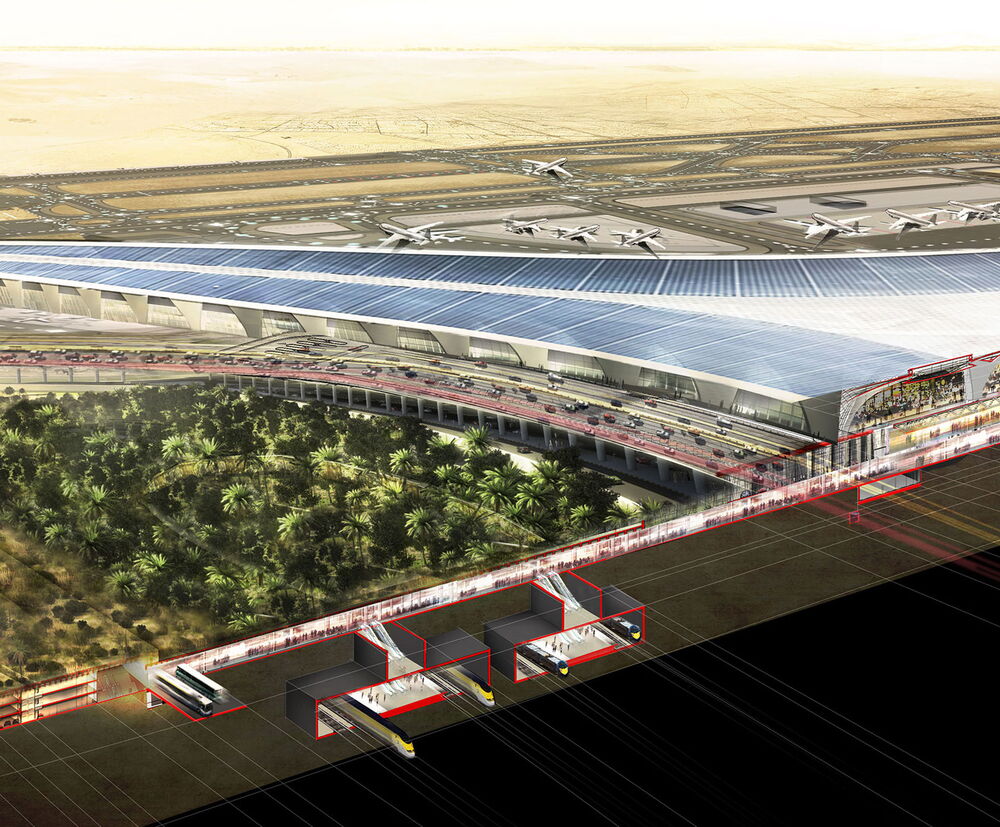

Forster + Partners, an internationally renowned architectural firm, is responsible for the structure. So it is hardly surprising that the terminal is impressive for visual reasons alone and will certainly make for an unforgettable stopover. The top view of the three-wing layout could also be inspired by the shape of a propeller. It consists of three symmetrical wings, each 1.2 kilometers long, which meet in a 25-meter high, imposing central space. Even during the construction phase, the terminal was equally impressive. The construction site covered around 3.3 million square meters and at times employed around 10,000 construction workers. To complete this size of a construction project on time, involving so many people and under difficult global pandemic conditions, is a tremendous achievement without equal. An achievement that the Turkish company LIMAK can take pride in.

Sunny Prospects: 12 MW of Rooftop Energy.

Around 42 °C [107.6 °F] outside temperature during the summer months and zero rain: There are easier places than Kuwait to efficiently create pleasant indoor climates. A significant contribution is provided by the roof structure. On the one hand, it keeps the heat out yet allows daylight to filter through to optimize artificial light sources. On the other hand, the roof surface also generates energy, thanks to the photovoltaic panels installed on it, which are intended to generate around 12 MW.

Air Handling Technology of a Special Magnitude.

robatherm also plays a key role in achieving the desired gold certification, and this is not a coincidence. After all, LEED certification attaches great importance to air quality. Up to 15 points can be achieved in this category alone. A minimum of 39 points is required to achieve the Gold certification. It therefore stands to reason that air handling technology played a significant role in this construction project.

robatherm produced a total of 225 air handling units for the new terminal. More than 600 containers were loaded with air handling units. For more than half a year, each week half a freight train with air handling technology made by robatherm traveled from Germany to the port in Triest in Italy, where it then continued its journey. If all the containers were lined up, it would take a pedestrian almost 2 hours to get from the first container to the last.

15 million cubic meters of air per hour.

Handling this large volume of air as efficiently as possible was one of this project‘s challenges. In these dimensions, energy recovery becomes a high priority. While in Germany, we usually speak of heat recovery. The same system also applies the other way around, in a simplified form as cooling recovery. Suppose the outdoor air temperature is higher than that of the consumed exhaust air. In that case, the temperature difference is used to cool the outdoor air. Through humidification, the air is also further cooled in an environmentally friendly manner. The built-in high-pressure humidifiers spray almost 29,000 liters of water per hour – or in other words: 191 bathtubs full.

Installed, dismantled, and rebuilt in Kuwait.

„Around 4 years have passed since initial contact was made to the point where the last AHU was shipped. Although the preparations were tremendous, it was a complete success for all involved,“ says Mathieu Huber, Managing Director at robatherm, as he looks back on the project. He visited Kuwait on several occasions. But delegations from Kuwait Airport and the responsible construction company from Turkey were also guests at robatherm in Germany. One highlight was the Factory Acceptance Test (FAT). During such a test, equipment is completely erected at the factory and tested while in operation. Not a rarity per se at robatherm, but certainly at this size. Several large units were fully mounted and ready for operation. A few years ago, such a set-up wouldn‘t have been feasible due to lack of space. Only with the new location in Jettingen-Scheppach do such possibilities exist. Over the course of several days and together with the customers, the devices were put through their paces. Various performance data were measured, compared with those values as promised by robatherm, and then confirmed.