Hidden Performance.

It‘s the heartbeat and lifeblood of functioning architecture: robatherm reveals insights into how its facility management works.

Buildings can be impressive. However, they are only really fascinating if their design, function, and operation are compelling. One crucial element is facility management. Thanks to the experience gathered at the Jettingen-Scheppach site, robatherm is now more familiar with this broad terrain than one might expect from a company specializing in air handling technology.

A Glimpse Behind the Scenes.

Facility management is like so much else in life. Work that doesn‘t come up in the first place needs not to be done either. And for precisely this reason, it was important for our administration building to avoid letting the sun rays create excessive heating from outside to keep the cooling demand as low as possible. The fully glazed upper floors accomplish this in two different ways: On the one hand, through a double façade with thermoinsulating glazing. In addition, an automated shading system is installed in the naturally ventilated maintenance aisle of the double façade, providing effective sun protection. On the other hand, the ground floor, almost entirely covered by a green mound, is protected from the heat influx from outside.

Comfortable and Climate-friendly Controlled Temperatures.

Efficient heat control in the administration building is primarily achieved via heated and cooled ceilings. Whereas in the meeting area, a 4-duct system with 6-way valves enables automated switching between heating and cooling all year round. A 2-duct system with selectable settings to either heating or cooling mode is in use in the offices. Thanks to an air discharge velocity of less than 0.2 m/s, working without experiencing any drafts is possible. Selected areas also feature underfloor heating or even cooling. Keeping the building at the right temperature is one thing, but generating the energy needed to do so is another.

Eco-friendly Interplay of a Variety of Technologies.

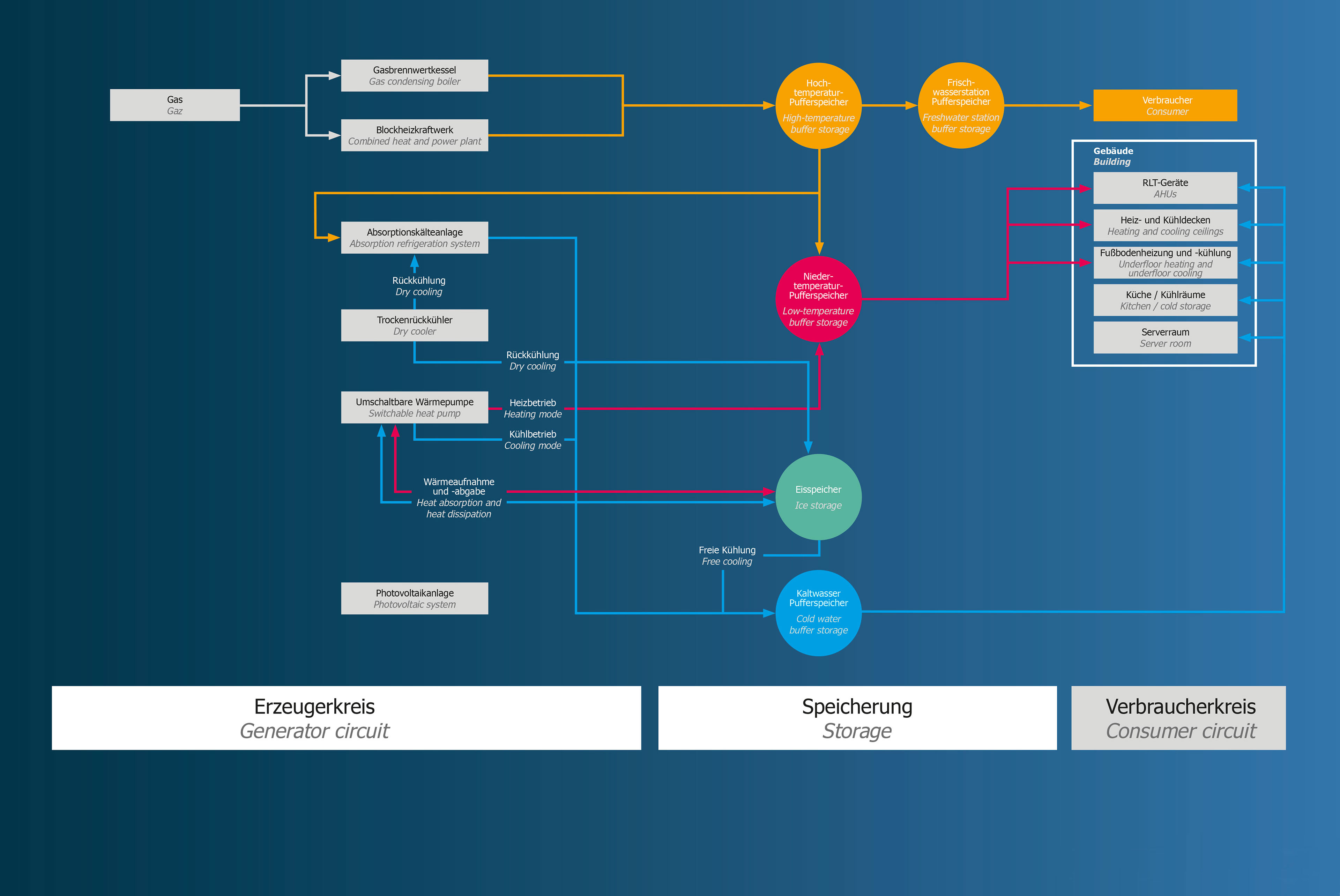

At robatherm, the commitment to efficient and future-oriented solutions was not limited to air handling technology. This commitment applies to the entire facility management system. The installation overview clearly shows that various technologies work together within robatherm‘s facility management. However, only the successful interaction of absorption refrigeration system, heat pump, photovoltaic system, combined heat and power plant, heat exchanger, and ice storage makes the operation of the building eco-friendly.

Indoor Climate from Our Own Facilities.

A total of four robatherm AHUs supply the administration building with absolutely clean air. The design with its deep black casing is very striking. For permanently safe hygiene, its interior is antimicrobial powder-coated. Both plate exchangers and rotors are used for heat recovery. All air handling units correspond to the energy efficiency class A+ (according to EUROVENT). It is demonstrated in air handling technology and throughout facility management: The prudent use of resources is a top priority at robatherm.

Automatically Adjusted and Centrally Regulated.

To control, regulate and monitor the facility management system efficiently, robatherm relies on state-of-the-art building control systems. This ensures that all components involved work optimally with each other and that their functions interlock seamlessly. Furthermore, thanks to our facility management‘s connection to the existing building control system in production, visualization, service, operational and error notifications, as well as operating records (trends), are bundled centrally.

Interested?

Please feel free to contact us. During a visit to our premises, it would be a pleasure to show you our facility management in detail. We look forward to an interesting exchange of experiences.

The technologies used at a glance:

One central element is the water/water-heat pump that has been developed by robatherm. This is a switchable four-stage combined installation for cold and hot water supply. The challenge was balancing extremely low temperatures during winter operations and exceptionally high temperatures during summer operations, combined with an ice storage system. A unique feature is the process reversal within the refrigeration circuit and the use of four plate heat exchangers. Switching had to be done between separate circuits of glycol-water and plain water, so four plate heat exchangers were installed instead of just two. Process reversal in the refrigeration circuit can save a great deal of space within the machine room, as the pipelines and valves‘ nominal sizes are significantly smaller compared to the water circuit.

For the production of cold water, robatherm relies on free cooling. This particular variant incorporates the ice storage tank: If the temperature in the ice storage tank drops below 15 degrees Celsius, this medium is used to cool the cold water buffer tank. This typically enables the server room, for example, to be cooled in an eco-friendly manner from November to May.

Another efficient solution is the integration of an absorption refrigeration system. In this thermal compressor, water serves as the coolant and lithium bromide as the solvent. The components used at robatherm achieve a cooling performance of 65 kW and draws heat from the high-temperature buffer storage.

The CHP could also be referred to as the heart of our energy and hot water production. It supplies the administration building with 50 kW of electricity and 80 kW of heat. During the winter, its power is used for heating. In the summer, the heat is used to operate the absorption refrigeration system to produce cold water. The economic and ecological advantage of the CHP is that robatherm puts all the energy to use directly on site.

A photovoltaic system was installed on the administration building‘s roof as a supplement to the CHP unit. Due to their East-West positioning, the 276 modules achieve lower peak output. However, thanks to their positioning, they generate electricity over a longer period of time over the day. Com-bined with the CHP, their share of self-generated electricity amounts to up to 75% of the wattage used by our administration offices in Scheppach.

As so-called latent heat storage, the ice storage can store energy all seasons long. Moreover, due to its feature of storing any waste heat, this technology barely loses any power. The storage system consists of an underground concrete basin holding a volume of 271 m³ [9570.27 ft³] of water where a 4,275 m [14025.59 ft] extraction heat exchanger is installed. The water gradually freezes up from the inside to the outside by heat dissipation to the heat exchanger. The purpose of this ingenious design is to take advantage of heat crystallization. This, among other things, is released when liquid water freezes into ice. By the way, during the transition to this solid-state of aggregation, the amount of heat released is the same as would be necessary to heat the same amount of water from 0° to 80° Celsius. To put it plainly: A considerable energy potential is made available during the winter months, which in turn, can be exploited throughout the year.

This is how the ice storage cools itself in the winter: By withdrawing warmth from the ice storage, the temperature drops and leads to the water icing up.

This is how the ice storage cools itself in the summer: In summer, the process is reversed, and it absorbs energy again. This means that the water changes from a solid to a liquid state of aggregation.

Interview

Manuela Engel works in Facility Management at robatherm. She takes care of, amongst other things, the facility management at our Jettingen-Scheppach location.

Everyone is talking about climate protection – can modern facility management make a contribution to this?

Manuela Engel: „Absolutely! With the help of modern facility management, it’s possible To create pleasant conditions within the room in as efficient a manner as possible. Given that energy resources are becoming scarce, the other alternative would be to reduce our standards in terms of comfort. However, that can‘t be the answer. Thus, facility management is our lever to enable comfortable, pleasant room conditions on the one hand. But, on the other hand, it allows us to use the energy we need in an efficient and environmentally friendly manner.“

How can one characterize robatherm‘s facility management?

Manuela Engel: „robatherm‘s facility management system is characterized by the fact that not only one solution is available. Instead, it is the interaction of a wide variety of technologies that makes truly efficient operations possible. This also applies to the building‘s energy concept, as it likely does apply to a country‘s energy policy. Ice storage, Combined Heat and Power Plant, heat pumps, photovoltaics, absorption refrigeration system, gas condensing boilers, and much more. It is the combination of many components that is characteristic of robatherm‘s facility management system.“

Keyword „efficiency‘‘ – how is the fully glazed administration building cooled during the summer?

Manuela Engel: „The question is often asked whether the offices turn into a sauna during the summer months. This is by no means the case. Before it comes to cooling, one should make sure that the building doesn‘t heat up that much in the first place. The double façade, with its ventilated maintenance aisle and automatic shading, helps keep the heat out. At night, we use the AHUs for night-time ventilation to cool the rooms with the help of the chilly outside air. To keep the rooms cool during the day, the chilled ceilings or, as on the ground floor, the underfloor cooling system is in use. Thanks to the heat pump and ice storage, as well as absorption refrigeration system in combination with the combined heat and power plant, we can efficiently provide the energy this requires.”

Do you have a component or mode of operation that particularly impresses you personally?

Manuela Engel: „I still find ice storage fascinating. It never ceases to impress me that we have a large underground basin here, which we can use as an energy storage facility throughout the seasons. While during the winter, we extract any remaining heat from the water, use it for the heat pump. Then, when we ice the water in the summer, it runs precisely Manuela Konrad arbeitet bei robatherm im Facility Management. Manuela Konrad works in Facility Management at robatherm. the other way around. The basic principle is as simple as it is efficient.“

Looks like robatherm has significantly expanded its expertise in facility management. What effect does that have on customers?

Manuela Engel: „As a manufacturer of air handling units, my colleagues are naturally very knowledgeable in this area. The corresponding facility management system naturally became a significant issue during the construction of our new production and administration buildings. This enabled us to gain valuable knowledge in other trades over the past few years. Again, we looked closely at a subject area, where many of our customers feel at home. I am confident that facility management at robatherm will also be of interest to them. Together, we will profit from these new perspectives. Especially the engineering room with the AHUs is definitely worth a visit.